Imagine your factory operating like a precision-geared machine, every part moving in perfect harmony without downtime or waste. This is exactly what an ERP system for factories offers you. It's not just an accounting software or inventory management tool, but rather the digital brain that brings all factory departments together on a single, integrated platform.

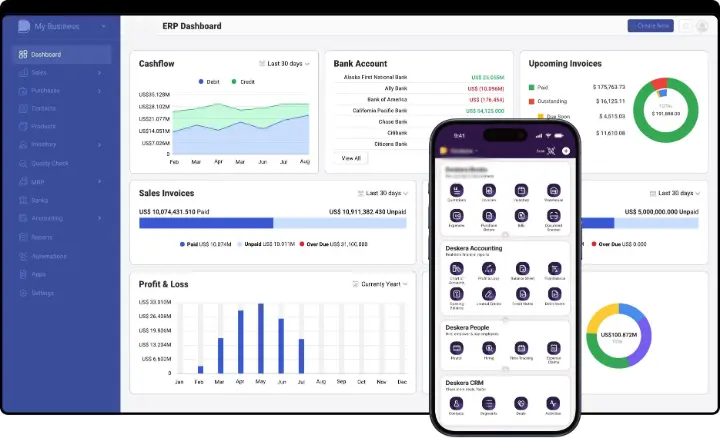

The real strength of the best manufacturing ERP software lies in its ability to boost operational efficiency, reduce human errors, monitor production lines in real time, and manage inventory levels with precision. On top of that, it generates detailed reports that empower you to make faster, smarter business decisions.

In short, ERP is the bridge that takes your factory from disorder to professionalism, and from guesswork to data-driven management. In this guide, we’ll walk you step by step through how to choose the best manufacturing ERP software that matches your factory’s needs and goals.

Why Do Factories Need ERP Software?

Many factories struggle when relying on multiple disconnected systems. This often leads to wasted time, lost resources, and difficulties in tracking production accurately. That’s where ERP software for factory operations becomes a complete solution, consolidating all administrative and production processes into one seamless system.

Here are some of the key benefits offered by the best manufacturing ERP software:

- Solving multi-system issues: Instead of juggling separate programs for inventory, production, and finance, ERP brings everything together in one integrated platform.

- Reducing waste and increasing productivity: By automating processes and monitoring every step of the production line, factories can cut down on waste and maximize resource utilization.

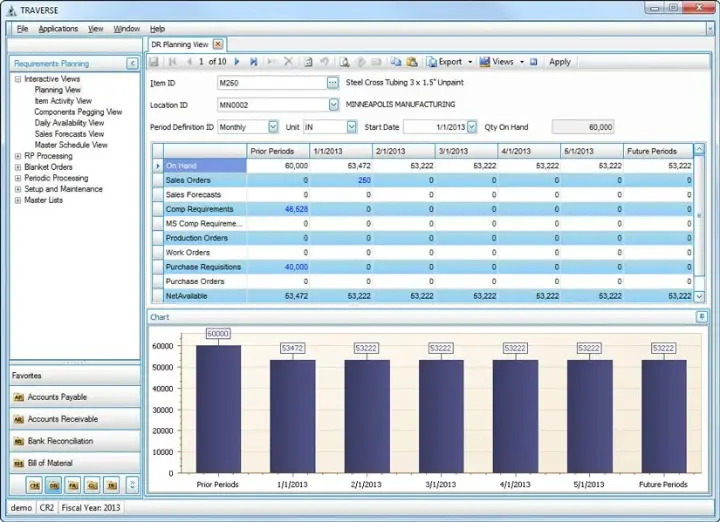

- Improving planning and resource management: ERP enables precise planning for production, inventory, and workforce, ensuring smooth and efficient workflows.

- Monitoring product quality: With real-time tracking and detailed analytics, factories can maintain high quality standards and meet compliance requirements.

- Accelerating decision-making: Accurate, real-time data allows managers to make strategic decisions faster and with greater confidence.

- Enhancing customer satisfaction: By ensuring timely deliveries and consistent product quality, factories can build stronger trust and loyalty among their customers.

How to Choose the Best ERP Software for Factory Management

Choosing ERP solutions for factory operations is more than just a technical decision; it’s an investment in the success and efficiency of your business. The right system can completely transform the way your factory operates, while the wrong one can add endless complexity and headaches. To avoid mistakes, here are the key criteria to keep in mind:

Ease of use and training:

The ideal system is one that any employee can use comfortably from day one, without hours of training. A clear interface, smooth workflows, and helpful learning resources make the transition enjoyable rather than stressful.

Integration with existing systems:

Your factory already relies on different software for inventory, accounting, or manufacturing. The best manufacturing ERP software integrates seamlessly with these tools, unifying everything under one roof without complications or data loss.

Industry-specific customization:

Not every factory is the same. Some require unique features, like tracking specialized production lines or managing scarce resources. Flexible ERP software that can be tailored to your needs is the secret to greater efficiency.

Smart production and inventory management:

Every second on the production line counts. ERP software allows precise monitoring of production, automatic inventory control, and real-time performance analysis turning factory management into a smooth, surprise-free process.

Error-free finance and accounting:

The best manufacturing ERP software doesn’t just manage production; it also ensures accurate tracking of costs, profits, and expenses, enabling smarter financial decisions at the right time.

Reliable support and regular updates:

With the right system, you never have to worry. Look for ERP solutions that come with 24/7 technical support and continuous updates to keep your factory aligned with the latest technologies.

Scalability with factory growth:

Your factory is growing and your ERP system should grow with it. Whether you’re adding new branches, production lines, or employees, the system must keep up without slowing down or causing interruptions.

Simply, choosing the best manufacturing ERP software means combining operational power with flexibility and ease of use, so your factory becomes smarter, faster, and more productive than ever before.

Why is UAnalyst the Best ERP Software for Factories?

If you are looking for ERP software for factory operations that combines flexibility, accuracy, and complete inventory control, then U Analyst a software development company is your ideal choice. This system is designed specifically to meet the needs of manufacturers especially those managing multiple warehouses offering innovative features that make inventory and production management easier and more efficient.

Key Features of UAnalyst for Multi-Warehouse Factories

1- Advanced Stock Ledger Report:

Unlike traditional systems that only display a list of stock movements, UAnalyst provides:

- A running balance for every movement.

- Product cost at each transaction.

2- Stock Ledger Excel Report:

- Export data directly into Excel.

- Filter by product, line, cost, category, customer, or date.

- Simplify analysis and support smarter decision-making.

3- Warehouse Restrictions:

- Restrict users from accessing unauthorized warehouses.

- Prevent unauthorized stock movements.

- Reduce human errors while increasing operational security.

4- UAnalyst Advanced Stock Management:

- Calculate the total cost of transfers between warehouses for each transaction.

- Display the total cost per individual line.

- Manage user permissions to control who can view or edit stock movements.

To cut it short, UAnalyst goes beyond traditional ERP software for factory management. It elevates inventory and production control to a professional level with detailed reporting, full control, and high security for every user making your factory smarter, more efficient, and ready for growth. Check our Software Development Services.

When choosing the best manufacturing ERP software, it’s not just about adopting a tool it’s about investing in your factory’s efficiency and long-term success. With UAnalyst, you get a complete solution that integrates inventory, production, and financial reporting into one powerful platform, with precise tracking and full control over user access.

Whether your goal is reducing errors, improving planning, boosting productivity, or ensuring product quality, ERP software for factory operations like UAnalyst delivers all this and more ensuring your factory runs intelligently, efficiently, and confidently in today’s competitive market.

Don’t let manual processes and scattered systems hold you back. Make UAnalyst your smart partner in factory management and start your digital transformation journey today.

U Analyst ERP Solutions 2025